UV Printing has become a versatile technology in both industrial production and creative applications. Using ultraviolet light to cure inks instantly, it works on diverse materials such as plastic, glass, wood, metal, and textiles, making it widely adopted in packaging, signage, and product customization.

In today’s competitive printing market, production efficiency is essential. Companies need faster turnaround, consistent quality, and lower costs—demands that require advanced printing equipment.

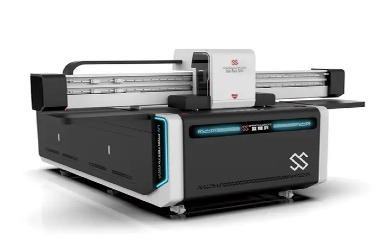

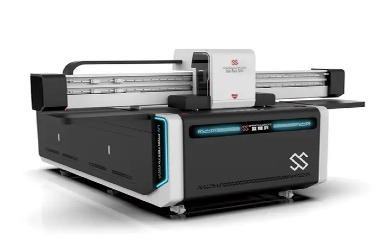

Modern UV flatbed printers deliver exactly that. With features like high-speed printheads, automated media handling, and intelligent ink systems, they enable higher output, reduced waste, and reliable results. This combination helps businesses stay competitive while improving profitability.

High-Speed Printing Technology

One of the key advantages of UV Printing is its ability to deliver high-speed results without sacrificing image quality. Modern UV flatbed printers are equipped with advanced technologies that streamline production, enabling businesses to handle larger workloads efficiently and meet tight deadlines.

1. Multi-Head Printing Systems

Simultaneous color and white ink printing: Traditional printers often require separate passes for white and color layers. Multi-head systems combine these processes, allowing both to be printed at the same time. This dramatically reduces printing cycles and accelerates job completion.

Reduced passes for faster job completion: With fewer passes needed to achieve the desired result, operators can complete more projects in less time, improving overall productivity while still maintaining sharp details and vibrant colors.

2. Advanced Printhead Technology

Precision droplet placement for consistent quality: Modern UV flatbed printers feature advanced printheads capable of controlling ink droplet size and placement with extreme accuracy. This ensures smooth gradients, fine details, and reliable consistency across different print jobs.

Longer lifespan and less downtime: New-generation printheads are designed for durability, minimizing wear even under high-volume use. With less frequent maintenance and replacement, businesses experience reduced downtime and lower operating costs.

By integrating multi-head systems and advanced printhead technology, UV Printing achieves a balance of speed and quality. This makes UV flatbed printers an ideal solution for businesses seeking to scale up production without compromising precision.

Automated Workflow Enhancements

Modern UV Printing technology goes beyond speed and quality—it also focuses on automation to simplify production workflows. Advanced features in UV flatbed printers reduce manual intervention, optimize job handling, and allow operators to manage complex printing tasks with greater efficiency.

1. Auto-Height Adjustment

Automatic detection of media thickness: UV flatbed printers can automatically sense the thickness of different substrates, from thin films to rigid boards. This ensures that the printhead maintains the optimal distance from the surface, preventing ink misalignment or damage to the media.

Saves setup time and reduces operator error: By eliminating the need for manual height adjustment, operators spend less time on preparation. This not only accelerates the setup process but also reduces the risk of human error, ensuring consistent, high-quality prints across various materials.

2. Intelligent Job Scheduling

Queue management for multiple print jobs: Intelligent scheduling systems allow operators to queue multiple projects and let the printer process them automatically in sequence. This improves workflow efficiency and ensures smoother transitions between different tasks.

Minimizes idle time between tasks: By reducing downtime during job changes, printers maximize output and shorten delivery times. This feature is especially valuable in busy production environments where continuous operation is critical.

With features like auto-height adjustment and intelligent job scheduling, UV Printing systems transform production workflows. Businesses benefit from faster setup, reduced errors, and streamlined operations, all of which contribute to higher productivity and profitability.

Versatile Media Handling

One of the key advantages of UV Printing is its ability to work with a wide range of substrates. Advanced UV flatbed printers are designed with versatile media handling systems that make it possible to produce stable, high-quality results across both rigid and flexible materials. This flexibility allows businesses to expand their application range and meet diverse customer needs.

1. Large Printing Bed and Vacuum Systems

Secure media fixation for stable output: A flatbed printer equipped with a large printing bed and a powerful vacuum system ensures that substrates remain firmly in place during the printing process. This prevents shifting, reduces print errors, and guarantees precise image placement.

Supports a wide variety of substrates: From wood, glass, and acrylic to ceramics, metals, and plastics, UV flatbed printers can handle nearly any material. This versatility allows businesses to explore applications in home décor, industrial components, promotional products, and more.

2. Roll-to-Roll and Hybrid Options

Expands capability from rigid to flexible media: With roll-to-roll or hybrid configurations, UV printers can seamlessly switch between rigid boards and flexible materials such as vinyl, canvas, or films. This adds greater versatility to production without requiring multiple machines.

Ideal for signage, packaging, and industrial applications: Whether producing large-format banners, retail displays, product packaging, or custom labels, hybrid UV printing systems deliver both speed and adaptability to meet different industry demands.

By offering large-format capability, secure media handling, and support for both rigid and flexible materials, UV Printing empowers businesses to serve multiple markets with a single system. This versatility not only improves efficiency but also creates new revenue opportunities.

Ink Efficiency and Eco-Friendly Features

Modern UV Printing emphasizes sustainability and cost-efficiency alongside speed and quality. Advanced UV flatbed printers reduce energy use, minimize ink waste, and expand substrate compatibility without compromising color output.

1. UV LED Curing Technology

Faster, energy-efficient drying: Consumes less energy than traditional lamps while enabling instant curing and higher production efficiency.

Broader substrate compatibility: Low heat allows printing on plastics, thin films, and heat-sensitive materials.

2. Smart Ink Management Systems

Reduced waste: Real-time ink monitoring ensures precise usage and consistent print quality.

Lower costs: Optimized ink consumption delivers vivid colors while minimizing operating expenses.

By combining UV LED curing and smart ink systems, modern UV Printing offers sustainable, high-quality results with lower costs and reduced environmental impact.

Software Integration and Precision Control

In UV Printing, hardware alone is not enough. Advanced software and precision control ensure accurate, consistent prints with minimal downtime, giving businesses a competitive edge.

1. Advanced RIP Software

Streamlined file processing: Converts designs into print-ready formats quickly, reducing setup time.

Color calibration: Supports ICC profiles for precise, consistent color across substrates.

2. Remote Monitoring and IoT Integration

Real-time status: Track printer operation, ink levels, and production remotely.

Predictive maintenance: Early warnings of potential issues reduce unexpected downtime.

By combining RIP software and IoT monitoring, modern UV flatbed printers deliver precision, reliability, and efficiency, enabling businesses to meet tight deadlines and achieve superior print quality.

Safety and User-Friendly Design

In industrial UV Printing, safety and ease of use are as vital as print quality and speed. Modern UV flatbed printers integrate intuitive controls and protective features to ensure both efficiency and security in demanding environments.

1. Operator-Friendly Interface

Touchscreen controls with icon-based menus simplify access to print settings, job queues, and maintenance.

Quick training: The user-friendly design reduces the learning curve, allowing new staff to operate efficiently and lowering training costs.

2. Safety Sensors and Dust Protection

Collision prevention: Built-in sensors detect obstacles and adjust printhead movement, protecting the printer and avoiding downtime.

Stable performance: Dust-proof covers safeguard components, extending lifespan and ensuring consistent results.

By combining intuitive interfaces with advanced safety measures, modern UV Printing systems deliver productivity, operator comfort, and workplace safety—helping businesses stay efficient without sacrificing reliability.

Conclusion

The advanced features of modern UV flatbed printers—from high-speed multi-head systems to automated workflows, versatile media handling, and eco-friendly ink management—are transforming the landscape of UV Printing. These innovations enable businesses to achieve faster turnaround times, reduce operating costs, and deliver consistently high-quality results.

By adopting advanced UV Printing solutions, companies can boost productivity, maintain competitive pricing, and expand their service offerings across industries such as signage, packaging, decoration, and industrial manufacturing.

For businesses aiming to stay ahead in today’s fast-paced printing market, investing in state-of-the-art UV flatbed printers is not just a technological upgrade—it’s a strategic move for long-term growth. Partnering with trusted suppliers ensures access to reliable machines, professional support, and continuous innovation.