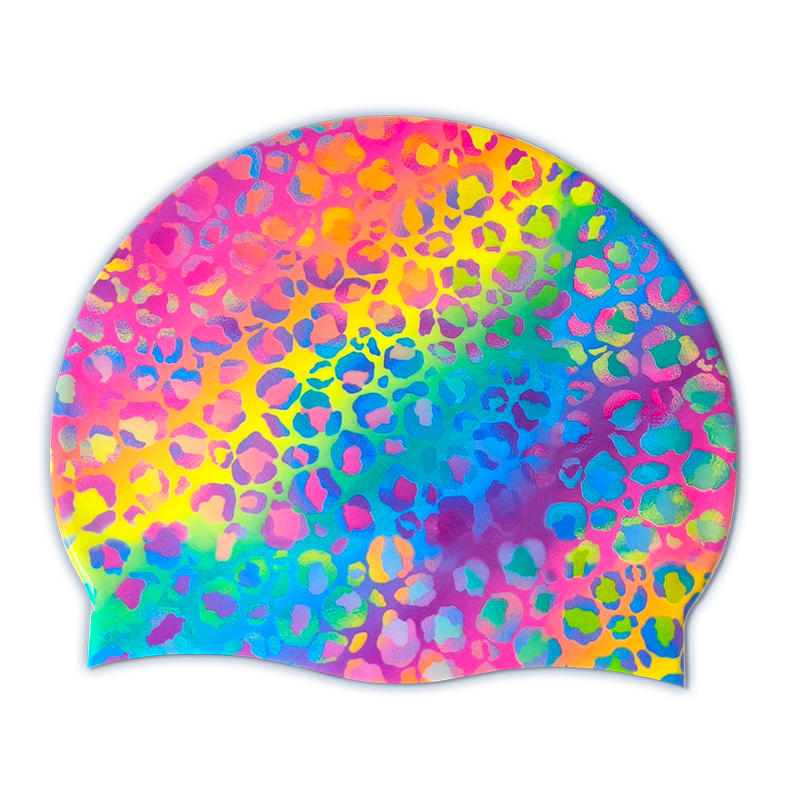

Our Silicone UV Printer Series offers a revolutionary leap in printing on silicone materials. Abandoning the cumbersome plate-making of traditional screen printing and breaking free from color constraints, it delivers vivid, precise patterns. This printer significantly cuts labor and material costs and is perfect for products like swim caps, eyeglass frames, and goggles. Now featuring customizable machine sizes, it ensures a perfect fit for your production needs, enhancing efficiency and flexibility for businesses prioritizing streamlined operations and eco-friendly practices.

Our Silicone UV Printer Series offers a revolutionary leap in printing on silicone materials. Abandoning the cumbersome plate-making of traditional screen printing and breaking free from color constraints, it delivers vivid, precise patterns. This printer significantly cuts labor and material costs and is perfect for products like swim caps, eyeglass frames, and goggles. Now featuring customizable machine sizes, it ensures a perfect fit for your production needs, enhancing efficiency and flexibility for businesses prioritizing streamlined operations and eco-friendly practices.

Precision UV Printing for Flexible Silicone Products

As a professional supplier of industrial silicone printing solutions, we provide high-performance silicone printing machines designed to deliver precise, durable, and vibrant prints on soft and curved silicone surfaces. From custom silicone bracelets and swim caps to promotional and industrial silicone parts, our machines combine advanced UV curing technology, wide format capability, and stable production performance — helping you scale your silicone printing operations.

What Is a Silicone Printing Machine?

A silicone printing machine is a UV digital printer engineered to print directly onto silicone materials. Standard flatbed printers struggle with silicone’s elasticity and texture, but silicone-optimized UV printing systems maintain ink adhesion, stretch resistance, and vivid detail on flexible silicone surfaces.

Unlike traditional pad printing, digital silicone printing enables:

Faster setup and changeovers

High-resolution graphics without plates

Efficient low to medium batch production

This makes silicone printing machines ideal for customization and industrial printing workflows.

Key Features of Our Silicone Printing Machines

Large Format Printing for Diverse Silicone Products

Our machines support large print areas:

Up to 600 × 1800 mm on larger units

Up to 400 × 1800 mm on mid-range units

This wide format range accommodates both large silicone caps and extended layouts for bracelets, bands, and other wearable silicone items.

High-Resolution Printing with UV LED Curing

All models use LED UV lamps for rapid curing and strong ink adhesion. Print quality ranges from 300 DPI up to 2400 DPI, enabling both high-speed production and fine detail work depending on your requirements.

Intelligent Protection & Reliable Ink Delivery

To reduce downtime and extend component life:

Intelligent spray head protection with automatic touch detection safeguards the printhead

Negative pressure ink system stabilizes ink flow and reduces clogging

Intelligent ink carriage lift secures the carriage during idle periods

These features support continuous production with minimal maintenance.

Easy Workflow Compatibility

Support for common image formats including TIFF, BMP, EPS, and JPEG gives you flexibility when preparing artwork. High-speed USB 3.0 data transmission ensures stable and fast file delivery.

Applications of Silicone Printing Machines

Our solutions are tailored for a broad range of silicone printing needs:

Wearable & Promotional Silicone Products

Industrial & Functional Silicone Components

Across all applications, silicone printing delivers vibrant, long-lasting prints even on curved and flexible substrates.

UV Silicone Printing vs Traditional Silicone Printing Methods

Compared to pad printing and analog techniques:

Digital UV printing eliminates plates and screens

Faster setup times increase throughput

Greater detail and color fidelity improve customization quality

Seamless changeovers for different designs without tooling

This makes UV silicone printing particularly suited to small batch runs, personalized products, and mixed orders — common scenarios in promotional and custom manufacturing.

How to Choose the Right Silicone Printing Machine

When choosing a machine, consider the following:

| Feature | What It Means for You |

| Print Size | Larger formats (600 × 1800 mm) suit wide products; mid-range formats (400 × 1800 mm) are ideal for bracelets, bands, and mid-size items |

| Resolution Range | Higher DPI options (up to 2400) deliver fine detail for graphics; lower DPI supports faster production |

| Ink System & Protection | Intelligent protection and negative pressure ink deliver consistent print quality and reduce downtime |

| UV Curing System | LED UV curing ensures strong adhesion on silicone, minimizes fade, and supports durable outdoor performance |

By matching product size, production speed, and print quality requirements with these specs, you can select the ideal silicone printing solution for your business.

Why Choose Our Silicone Printing Solutions

We deliver professional silicone printing machines designed for today’s manufacturing demands:

Broad application support — from promotional goods to industrial components

High-accuracy printing with robust UV LED curing

Intelligent protection systems for stable, long-term operation

Flexible format support and easy workflow integration

Whether you’re launching a custom silicone product line or scaling existing production, our machines give you reliable performance and superior print quality.

Get a Custom Silicone Printing Solution

Looking for tailored recommendations or sample testing before you buy?

Contact us today for:

Contact Us for Silicone Printing Solutions