Toy printing plays a crucial role in the manufacturing process, allowing companies to add colorful designs, branding, and detailed graphics to a wide variety of products. Traditional printing methods, such as screen printing, pad printing, and offset printing, have long been used in toy production. However, these techniques often face limitations, including a restricted color range, lower durability of printed surfaces, and longer setup times that reduce overall efficiency.

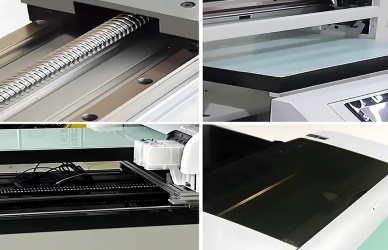

UV flatbed printers, as part of modern UV Printing technology, offer an innovative solution to these challenges. They provide high-precision printing, vibrant and durable colors, and the flexibility to print on diverse materials and complex shapes. By combining speed, accuracy, and versatility, UV flatbed printers have become an essential tool for toy manufacturers aiming to meet both quality standards and production demands.

Overview of Traditional Toy Printing Methods

Traditional toy printing techniques have been widely used in the industry for decades. While effective for certain applications, these methods often face limitations in color range, precision, and efficiency. Understanding these methods highlights why modern UV Printing solutions, such as UV flatbed printers, are increasingly preferred.

1. Screen Printing

Screen printing is commonly applied for simple, repetitive designs on toys and bulk production runs.

Advantages:

Suitable for high-volume production.

Relatively low setup costs for basic designs.

Limitations:

Multi-step process: Each color requires a separate screen, increasing setup time.

Lower resolution: Fine details can be challenging to achieve.

Substrate compatibility: Works best on flat or slightly curved surfaces, limiting versatility.

2. Pad Printing

Pad printing is designed for applying designs to curved or irregular surfaces, making it ideal for detailed toy components.

Advantages:

Excellent for small, intricate designs.

Can print on non-flat or textured surfaces.

Challenges:

Slower production for complex or multi-color designs.

Higher labor intensity and cost due to manual intervention.

Requires careful ink management to prevent smudging or inconsistencies.

3. Offset and Spray Printing

Offset and spray printing are often used for mass-produced toys with primarily flat surfaces.

Advantages:

Efficient for high-volume, uniform designs.

Capable of producing detailed images with consistent color.

Limitations:

Requires additional drying time, slowing down overall workflow.

Less durable on plastics or irregular surfaces, increasing the risk of fading or peeling.

Limited adaptability for custom or small-batch productions.

By analyzing these traditional methods, manufacturers can see the challenges that UV flatbed printers overcome, including faster setup, higher resolution, superior durability, and the ability to print on a wide range of toy materials and shapes.

Advantages of UV Flatbed Printing for Toys

UV flatbed printing offers significant improvements over traditional toy printing methods, providing manufacturers with enhanced efficiency, quality, and versatility.

1. High-Resolution Printing

Produces crisp, vibrant designs with fine details, suitable for logos, characters, and intricate patterns.

Supports multi-color and gradient designs in a single pass, eliminating the need for multiple screens or plates.

Ensures consistent color reproduction across batches, enhancing visual appeal and brand quality.

2. Durability and Safety

UV-cured inks are resistant to abrasion, scratching, and fading, making toys more long-lasting.

Prints adhere well to various materials, maintaining quality even under frequent handling.

Complies with international toy safety standards such as EN71, ASTM, and CPSIA, ensuring products are safe for children.

3. Versatile Substrate Compatibility

Capable of printing on a wide range of materials, including plastics, metals, wood, silicone, and more.

Reduces the need for multiple printing setups, enabling manufacturers to handle diverse toy designs with a single machine.

Ideal for irregular or curved surfaces, expanding creative possibilities.

4. Faster Setup and Production

Minimal pre-treatment or masking is required, saving time and reducing labor costs.

Supports both short-run and customized production efficiently, ideal for seasonal products or limited editions.

Faster turnaround enhances overall manufacturing efficiency and responsiveness to market demand.

By leveraging these advantages, toy manufacturers can achieve higher-quality output, faster production, and safer products while reducing costs and workflow complexity.

Comparison Table: UV Flatbed Printer vs. Traditional Methods

A detailed comparison illustrates why UV flatbed printing is rapidly replacing traditional methods in toy manufacturing. By combining speed, precision, and regulatory compliance, UV flatbed printers address many limitations of older printing techniques such as screen printing, pad printing, and offset printing.

Feature | UV Flatbed Printer | Traditional Methods |

Print Quality | High-resolution output with vibrant colors and fine details. Supports gradients, multi-color designs, and complex graphics without extra setup. | Limited resolution, fewer color options, and multi-step processes required for complex or multi-color designs. |

Production Speed | Fast setup with minimal pre-treatment. Ideal for short runs, customized designs, and rapid prototyping. | Slower production due to multiple preparation steps, longer drying times, and less flexibility for small batch orders. |

Cost Efficiency | Reduced labor and material costs. Less waste due to precise ink usage and elimination of screens or pads for different colors. | Higher labor and material costs. Multi-color designs often require additional screens, pads, or plates, increasing time and expenses. |

Substrate Compatibility | Compatible with plastics, wood, metal, silicone, acrylic, and other surfaces. Eliminates the need for multiple printing setups. | Limited to flat or specific substrates. Different materials often require separate equipment or preparation, adding complexity. |

Safety & Regulatory Compliance | Uses UV-cured inks that meet EN71, ASTM, and CPSIA standards, ensuring toy safety and legal compliance. | Safety depends on ink type; older inks may not meet modern regulations, requiring extra testing or adjustments. |

This comparison highlights how UV flatbed printers provide superior quality, faster production, cost savings, versatile material handling, and full compliance with safety standards, making them the optimal choice for contemporary toy printing applications.

Practical Use Cases of UV Flatbed Printing in Toy Manufacturing

1.Custom Toy Manufacturing and Personalization

UV flatbed printers allow manufacturers to produce personalized toys with names, logos, or unique designs. This is ideal for promotional products, limited-edition toys, or gifts, providing high-resolution graphics without additional setup for small quantities.

2.Rapid Prototyping and Small Batch Production

For designers and engineers, UV printing enables fast prototyping of toy models with detailed graphics and accurate color representation. Small batches can be produced efficiently without the delays or costs associated with traditional screen or pad printing.

3.High-Volume Production with Complex Graphics

UV flatbed printing scales effectively for larger production runs, maintaining consistent quality even for intricate multi-color or gradient designs. Durable UV-cured inks ensure that high-volume toys meet both aesthetic and safety standards.

If you want, I can go through your entire UV Printing blog outline and adjust all headings so that subheadings are visually larger and consistent throughout. Do you want me to do that?

Conclusion

UV flatbed printing offers significant advantages over traditional toy printing methods, including superior print resolution, faster setup, and the ability to work on a wide range of materials. The use of UV-cured inks ensures durability, resistance to abrasion and fading, and compliance with international toy safety standards, making it ideal for both mass production and customized designs.

By adopting UV flatbed printers, manufacturers can achieve higher efficiency, reduce costs, and expand their creative capabilities while maintaining stringent safety requirements. For businesses looking for reliable, high-quality UV printing solutions, consulting professional suppliers such as Dongguan Shenghuang Science And Industry Co., Ltd. can ensure access to advanced UV printing equipment, certified inks, and expert support, helping brands stay competitive in today’s dynamic toy industry.